'Made in China' cannot easily be replaced

Nation boasts important technological advantages, according to top experts

Consumers in the United States and other Western countries face rising prices as a result of Chinese companies being isolated from global supply chains, according to leading experts.

The aggressive trade policy being pursued by the US administration, particularly in relation to the technology sector, is likely to backfire, pushing up the price of many goods, especially those in the consumer electronics sector, the experts said.

The economist Stephen Roach, senior fellow at Yale University's Jackson Institute for Global Affairs, said US companies are likely to source components from higher-cost producers.

"The result is the functional equivalent of a tax hike for US consumers," he said.

Richard Martin, managing director of IMA Asia, the influential peer group forum for regional CEOs, said attempting to cut China out of supply chains is destined to fail and will also result in rising costs.

He said some US-bound production is being moved from the Chinese mainland to Vietnam, Taiwan, India and Indonesia, but invariably all these locations then import components and materials from the mainland.

"Ultimately, it is not really decoupling the US and China, just forcing trade diversion, which raises the cost for the US," Martin added.

There is evidence that since the US unilaterally imposed tariffs on Chinese goods in 2018, global supply chains have felt the impact.

Last year, Chinese exports of a basket of 1,200 products accounted for 22 percent of the global total, down by 3 percentage points from the previous year, according to a study by law firm Baker McKenzie and economics consultancy Silk Road Associates.

However, the focus this year has been on the technology sector. On Aug 17, the US administration said it aimed to cut off supplies of foreign semiconductors to Chinese telecommunications giant Huawei and 38 of its affiliated companies, escalating a move made initially in May.

The announcement caused consternation among US semiconductor manufacturers that rely on sales to China.

"These broad restrictions on commercial chip sales will bring significant disruption to the US semiconductor industry," said John Neuffer, president and CEO of the US Semiconductor Industry Association.

To add to the confusion, US President Donald Trump this month ordered a ban on WeChat, the Chinese messaging, social media and mobile payment app, being available on Apple devices.

The decision could have disastrous implications for Apple, which derives 20 percent its sales from China. WeChat, owned by Tencent Holdings, is a vital platform for many US retailers and gaming companies. It is still not clear where or how such a ban would be applied.

Meanwhile, China is boosting its semiconductor industry in the hope of becoming a player in advanced chips, with the State Council announcing that some manufacturers will be exempt from corporate tax for up to 10 years.

Abishur Prakash, a geopolitical futurist at the Center for Innovating the Future, a strategic consultancy company based in Toronto, Canada, said recent events have been very confusing for many companies in the technology sector, but he thinks it will be difficult to extricate China from supply chains.

"While companies move supply chains-from manufacturing to parts-to Southeast Asia, these factories are not producing the most-critical components. In the short term, companies will remain dependent on China," he said.

However, Prakash is concerned that the world of technology is becoming polarized.

"Both the US and China realize that dependency on each other, from a tech point of view, isn't going to work. The US doesn't want Chinese technology such as TikTok (the video-sharing service also at the center of a US-China dispute) or Huawei's 5G, and China doesn't want to be dependent on US technology such as chips, software and servers," he said.

Prakash believes that companies faced with this situation will increasingly begin to look for neutral destinations to source products.

"It's not about economic benefits, it's about business. By moving supply chains, companies are ensuring that their lucrative products aren't hindered by geopolitics," he said.

Roach, from Yale University, the author of Unbalanced: The Codependency of America and China, said the US' aggressiveness in trying to block China out of supply chains belies its own weak economic position.

The former Asia chairman of investment bank Morgan Stanley, where he was also chief economist, said, "For the US, with its massive shortfall of domestic savings, there can be no decoupling in the broad sense from the rest of the world.

"With the savings shortfall going from bad to worse in the face of the COVID-related explosion of federal budget deficits, the current account and trade deficit will rise dramatically.

"Politically-inspired decoupling with China will simply shift the Chinese piece of America's overall multilateral trade deficit, which it had with 102 nations in 2019, to another producer. This is akin to rearranging the deck chairs on the Titanic."

Edward Tse, an expert on the Chinese technology sector and author of China's Disruptors: How Alibaba, Xiaomi, Tencent and Other Companies are Changing the Rules of Business, said despite the pressure from the US, China remains highly resilient.

He cited the rapid recovery from the coronavirus pandemic by Asian supply chains, many of which are centered on China.

"East Asian countries have handled the COVID-19 pandemic better than most other nations, particularly the US. We can also see manufacturing supply chains beginning to recover," he said.

Tse, the founder and CEO of management consultancy Gao Feng Advisory, said the scale and sophistication of Chinese supply chains are often overlooked in the current debate.

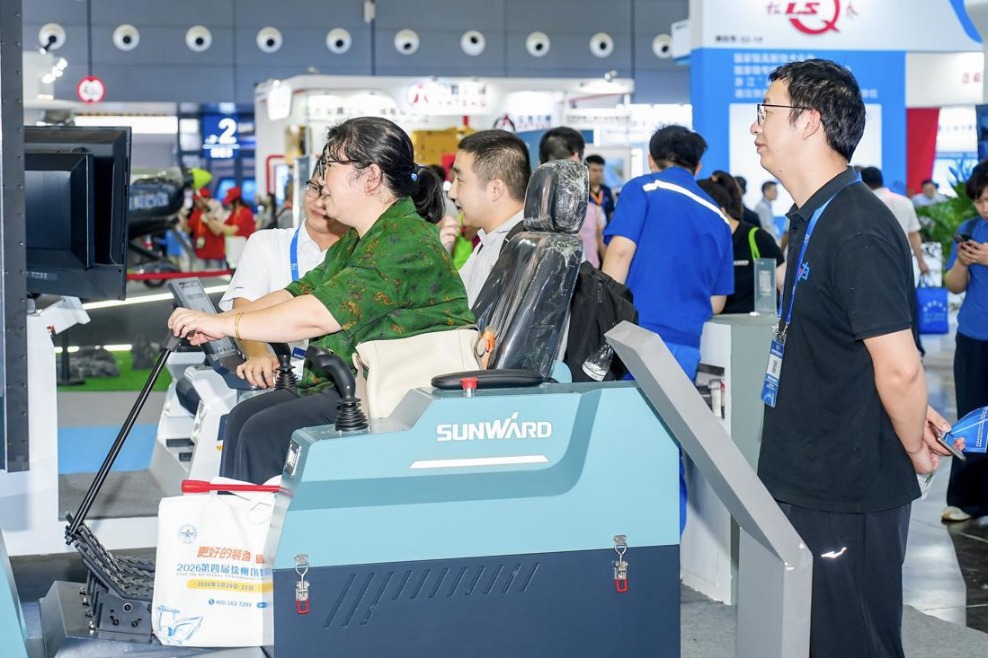

"China can do things that other countries simply cannot do. When external customers want innovative new products, they want people who can quickly do design, prototyping and can manufacture quickly in batches. The Chinese are very good in doing that. They are very entrepreneurial and what you have in China is a very dynamic process," he said.

Aidan Yao, senior emerging Asia economist at Axa Investment Managers in Hong Kong, said that while the US has turned up the heat on supply chains, the pandemic has hit companies so hard that they will be unwilling to make any drastic changes.

He argues that it costs money to switch production, and many companies are now so low on cash that they cannot make major investment decisions.

"Even if some companies wanted to move out of China, investment plans have been significantly scaled back because of the pandemic," he said.

Yao also believes many companies have fostered such strong supply networks in China that it will be difficult for them to move.

"China didn't become the world's factory overnight. It was 30 or 40 years in the making, and there are reasons why multinationals have put their supply chains in China. It is not because they necessarily love China-they are there for sound commercial and economic rationalities. None of these have changed."

Thomas Luedi, a partner based in Shanghai for Bain and Co, the management consultancy, said that no matter the politics, many companies will avoid making rash moves.

He said that in recent years companies have tended to pursue a China-Plus-One strategy in constructing their supply chains, which could involve having a production plant in China and another in Southeast Asia.

"Companies do this in a strategic manner. There is no sudden closing of plants in China and haphazard opening of other ones in new countries. Companies who do this, in fact, don't tend to close their China operations at all. It is all part of their long-term planning," he said.