Master craftsman speaks visual language

"Each of these can stand alone in creating a complete artwork," he says.

For instance, many traditional teapots or wine vessels are made using only zhitai, while historical examples like gold crown from the Ming Dynasty are purely huasi, he says.

One of his decorative screen works is currently on display at the China National Arts and Crafts Museum, which utilizes zanke to depict the majesty of the Great Wall in vivid details.

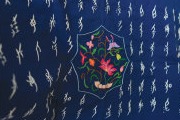

Adding to the richness of his current celestial maiden piece is the application of shaolan (blue-enamel firing technique), another important element of filigree inlay.

Yuan uses this technique to bring vibrant colors to the otherwise monochromatic silver base.

While many people associate enamel with cloisonne, Yuan clarifies that his method uses silver as the base and a different type of high-temperature glaze.

By combining wire outlining (qiasi), filigree filling, and colored enamel, he brings to life the intricate patterns and textures of the celestial figure's clothing.

Yuan holds many distinguished titles under his belt — traditional Chinese arts and crafts master and third-generation inheritor of filigree inlay, designated as a national intangible cultural heritage in 2008.

His exquisite works have won multiple international awards, including the United Nations award for promoting intangible cultural heritage in October.

Over the years, he has restored and replicated hundreds of cultural relics for nearly 100 museums across China. Among his most celebrated achievements, the filigree-inlaid clutch bags and brooches he and his team created served as national gifts for the 2014 APEC Summit in Beijing.

A native of the capital city's northeast Miyun district, Yuan developed a love for art during his school years.

In the early 1990s, he joined a Changping arts and crafts factory, drawn by the sheer beauty of its products and the dream of becoming a designer who could draw every day.

Since the factory specialized in filigree inlay, Yuan cut his teeth on every step of the intricate production process, staying two or three hours after his shift ended to refine his skills.

During training in engraving metal, he once struck his left index finger with a small hammer. Blood streamed down, but he continued hammering, then another blow landed on the same wound, he recalls.

To this day, he bears a small scar on that finger. His persistence paid off, and he soon became a master engraver.